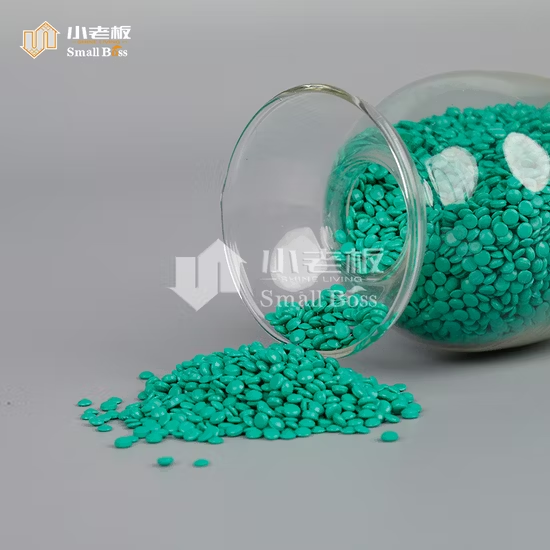

Flexible PVC Compounds St2 for Electric BV Cable Insulation

PVC Compounds ST2 for Electric BV Cable Insulation Description: PVC Thermoplastic Compound suitable for power, telecommu

Send your inquiryDESCRIPTION

Basic Info

| CAS No. | 9002-86-2 |

| Material | Polyvinyl Chloride/PVC |

| Usage | Wire Cable |

| Plastic Properties After Heated | Thermoplastic Plastics |

| Plastic Forming Method | Extrusion |

| Color | Any Color |

| Transport Package | 25kg |

| Specification | 70-----110degree |

| Trademark | longtai |

| Origin | China |

| HS Code | 3904220000 |

| Production Capacity | 10 Tons Per Day |

Product Description

PVC Compounds ST2 for Electric BV Cable InsulationDescription:

PVC Thermoplastic Compound suitable for power, telecommunications, robotics, automotive, fiber optics and many other cables with operating temperature between -40°C and +125°C. Upon request with higher fire retardant properties, special resistance to oils, hydrocarbons and many other chemical and natural agents.

Package is normal bag (25kg) or jumbo bag (800-1000kg).

| Tensile strength | MPa | 20.5 |

| Fracture tensile strain | % | 320 |

| Ageing temperature | ºC | 100 |

| Ageing time | h | 168 |

| Tensile strength after ageing | MPa | 22.5 |

| Max change of tensile strength | % | +12 |

| After ageing fracture tensile strain | % | 290 |

| Max change of fracture tensile strain | % | -10 |

| Thermal deformation | % | 28 |

| Thermal ageing quality loss | g/m2 | 19 |

| 200ºC thermal stability time | min | 90 |

| 20ºC volume resistivity | Ω.cm | 2.0*1011 |

2. Technical specifications of 90 ºC pvc resin compound

| Tensile strength | MPa | 20 |

| Fracture tensile strain | % | 330 |

| Ageing temperature | ºC | 100 |

| Ageing time | h | 240 |

| Tensile strength after ageing | MPa | 21.5 |

| Max change of tensile strength | % | +8 |

| After ageing fracture tensile strain | % | 310 |

| Max change of fracture tensile strain | % | -6 |

| Thermal deformation | % | 28 |

| Thermal ageing quality loss | g/m2 | 9 |

| 200ºC thermal stability time | min | 120 |

| 20ºC volume resistivity | Ω.cm | 2.0*1010 |

Who we are:

1) Specialized manufacturer;

2) Established in 2002, successfully listed the New OTC Market in 2016, stock code: 836898;

3) More than 200 employees;

4) Company type: OEM/ODM;

5) World market: more than 40% of product are export to Europe, America, Japan, Southeast Asia and Africa, and so on;

6) Products : Agriculture twines, Package ropes, Cable materials and Textile materials;

7) All products meet RoHS and REACH by SGS.

PVC Thermoplastic Compounds for cables Storage :

These compounds must be stored at ambient temperature (not exceeding 30'C) in closed and unbroken packaging ,in order to avoid exposure to sunlight and water absorption.

Welcome to inquiry!

Related Products