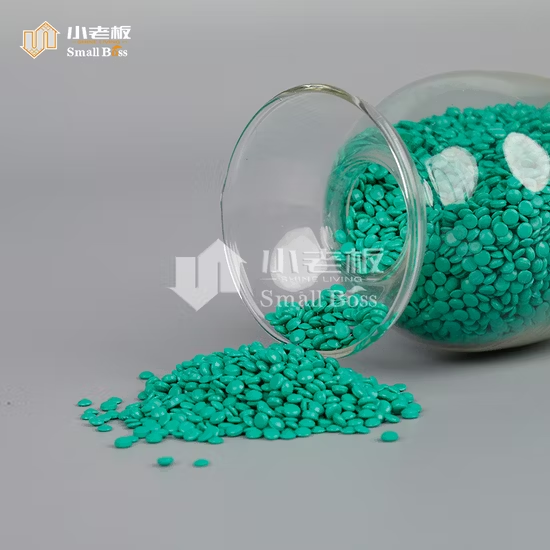

Factory High Quality Plastic Virgin Soft PVC Raw Material Plastic Granule for Door Gasket

Overview Product Description Product description Our company develops and develops PVC refrigerator pellet products, ado

Send your inquiryDESCRIPTION

Basic Info

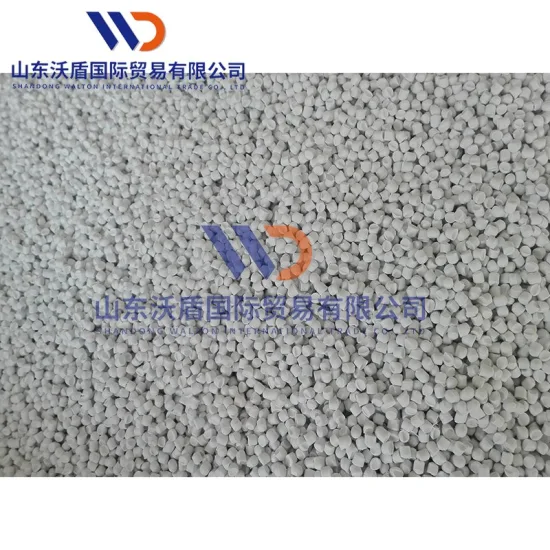

| Model NO. | PVC Granule |

| Carrier | PVC |

| Color | White |

| Certification | ISO, CE |

| Plastic Forming Method | Extrusion |

| Usage | General Plastic |

| Material | Polyvinyl Chloride/PVC |

| Customization | Available |

| Transport Package | as Required |

| Specification | Standard |

| Trademark | SD Walton |

| Origin | Shandong/China |

| HS Code | 84778000 |

| Production Capacity | 100 Tons/Month |

Product Description

Product description

Our company develops and develops PVC refrigerator pellet products, adopts imported new plasticizers, and solves the volatilization loss of plasticizer to the gas phase, the loss to the liquid phase, and the migration loss to the solid phase polymer material through the optimized design of the formula. Overcoming the phenomenon of fogging, oozing, softening, embrittlement and pollution of plastic products caused by plasticizer migration, so that the physical and mechanical properties of plastic products are permanently maintained.

Detailed PhotosFeatures

1. Very low volatility2. Excellent resistance to extraction3. Excellent migration resistance4. Excellent low temperature resistance

PVC

PVC resin is the most widely raw material used in plastic production. It has good chemical stability corrosion resistance and water resistance. It can be dissolved in hydrochloric ether, ester and some alcohol . It can offer good solubility , good electrical insulation , thermoplasticity and membrane forming capacity.PVC used to be the world's largest production of general plastic, the application is very wide.In building materials, industrial products, daily necessities, floor leather, floor tile, artificial leather, pipe, wire and cable, packaging film, bottle, foam materials, sealing materials, fiber and other aspects are widely used.

Material | 100% virgin PVC resin + Eco-friendly additives |

Hardness | ShoreA35-A75 |

Density | 1.20-1.55 g/cm3 |

Processing | Extrusion Moulding |

Color | Black, White, Grey, Brownm, Transparent, Natural, Red or Customized |

Certification | RoHS, REACH, PAHS |

Application | Seal Strip, Seal Strip Lining, Gasket Strip Plasticized PVC Gasket, Padding Strip, Automotive Sealing Window & Door Seal, Refrigerator & Freezer Sealing Cabinet Seal, Noise Seal, Weather Sealing Gasket PVC Seal Protector, Anti-Slip Seal, Water Stopper Seal Weather Stripping, Edge Trim Seals Strip Hollow PVC Bulb Seals , PVC Nitrile(NBR)Combined Seal Soft Rigid Composite Seal |

Basic Features | Eco-friendly. No Smell. Non Toxic |

Weather Resistant. Deformation Resistant | |

Attractive Cost Performance | |

Good Flexibility. Good Tensile Strength | |

Excellent Impact Characteristics | |

Good Chemical Resistance | |

Excellent Thermal Stability | |

High Processing Performance |

Our company is a high-tech enterprise integrating scientific research, design, production and sales. Relying on technological progress, it is our constant pursuit to continuously provide users with satisfactory products. Our company's marketing planning department has created a valuable core force for corporate customers. In terms of depth, manufacturing power, and actual combat power, it can gain insight into industry trends and consumer psychology trends that customers cannot perceive.

Packaging & ShippingConvenient Transportation

Our company and factory are located in Qingdao, Shandong Province. Qingdao Port was opened in 1892. It is located in the center of China's Bohai Rim port group and the Yangtze River Delta port group. It occupies the center of the Northeast Asian port circle and is an important international trade hub in the Western Pacific. , is currently one of the largest comprehensive ports in the world.FAQ

FAQ

1. Why choose us?

We are a professional manufacturer developing equipments such as plastic extruder, spiral welded pipe machine, ring rolling machine and activated carbon, established in Qingdao in 2002. With 20 years experience in mechanical design and production. In recent years, we have established an international trading company with the conditions for independent export, and our equipment has been exported to more than 100 countries.2. What services do we provide?Pre-sale communication → design plan, signature confirmation → custom production → test machine before shipment → packaging and delivery → engineer installation → operator training → technical support3. InspectionAfter the machine is completed, the seller shall notify the buyer to inspect the goods before shipment, and the seller guarantees that all goods sold are in good condition. The seller shall bear the material cost for inspection at the seller's factory. The buyer shall go to the seller's factory for inspection work, or the buyer can entrust any third party to the seller's factory for inspection work.4. Installation and equipment debuggingThe seller shall send a technical team to the buyer's factory to install and debug the whole line, and the buyer shall bear the full food/ground and round-trip tickets (airplane, food, hotel, etc.), and pay the engineer $100/day/engineer.

If you have any questions, please contact us directly!You can message us ↓↓↓↓↓↓↓↓↓

Related Products