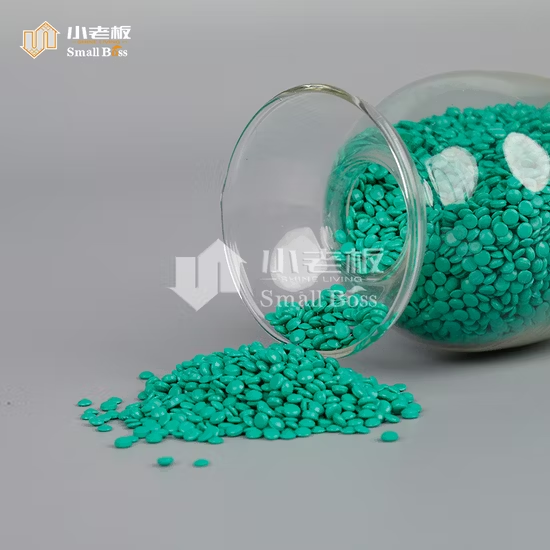

ETPU Beads Extrusion Production Line / ETPU Middle Sole Shoe Making Foaming Machine

ETPU Beads Extrusion Production Line / ETPU Middle Sole Shoe Making Foaming Machine 1. TPU Drying System2. Raw Material

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | ES-95T |

| Assembly Structure | Integral Type Extruder |

| Screw | Twin-Screw |

| Engagement System | Intermeshing |

| Screw Channel Structure | Non Deep Screw |

| Exhaust | Don′t Exhaust |

| Automation | Automatic |

| Computerized | Computerized |

| Transport Package | Wooden Case |

| Trademark | FEININGER |

| Origin | China |

| HS Code | 8477402000 |

| Production Capacity | 5 Sets/ Month |

Product Description

ETPU Beads Extrusion Production Line / ETPU Middle Sole Shoe Making Foaming MachineBasic Configuration |

Packing & Delivery

Feininger has been engaged in foam extrusion technology and its industrialization for years. We are located in China with the global view. Nowadays, Feininger becomes the leading supplier for both XPS board extrusion line and XPS insulation board all over the world. And we have successfully been developed PET foam board extrusion line, PS baseboard line and PS photo frame making machine. Success in plastic foam extrusion requires experiences and innovation. Feininger R&D center did it. This enables Feininger become your reliable business strategic partner with confidence. People have to mention Feininger whenever they talk about new foam extrusion technology. From consulting to commissioning, we offer completely turn-key project for foam extrusion plant. Feininger had been passed ISO:9001 and CE certificates which guaranteed our products to have higher quality requirements and more caring designs. Our mission is to have more customers who come from all over the world could use our products and service by our unceasing efforts.FAQ1. who are we?

We are based in Jiangsu, China, start from 2003,sell to Eastern Asia(60.00%),Mid East(20.00%),South Asia(10.00%),Africa(10.00%). There are total about 201-300 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us?

XPS Production Line, XPS Foam Board,PET Extrusion Line,PS Skirting Board Production line,PS Photo Frame Extrusion Production Line

4. why should you buy from us not from other suppliers?

In the year of 2002, Feininger firstly designed and manufactured high quality XPS Foam Board Production Line in China. Since then we have contributed us to research of XPS technology improving continuously product quality.

5. what services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, CNY;

Accepted Payment Type: T/T, L/C;

Language Spoken: English, Chinese ,Russian

Related Products

-

![PVC Shrink Film Granules]()

PVC Shrink Film Granules

-

![Resin Powder Granules Virgin Recycled Materials /PVC Resin Powder Sg8 Soft PVC Scrap PVC Granules Production Line]()

Resin Powder Granules Virgin Recycled Materials /PVC Resin Powder Sg8 Soft PVC Scrap PVC Granules Production Line

-

![100% Virgin/Recycled Granules PVC PVC Granule Extrusion Cheap Price]()

100% Virgin/Recycled Granules PVC PVC Granule Extrusion Cheap Price

-

![Factory High Quality Plastic Virgin /Recycled PVC Raw Material/PVC Compound/PVC Granules for Shoe, Slipper, Wire and Cable]()

Factory High Quality Plastic Virgin /Recycled PVC Raw Material/PVC Compound/PVC Granules for Shoe, Slipper, Wire and Cable